Update: If you’d like to see a video on this puppet. Click here!

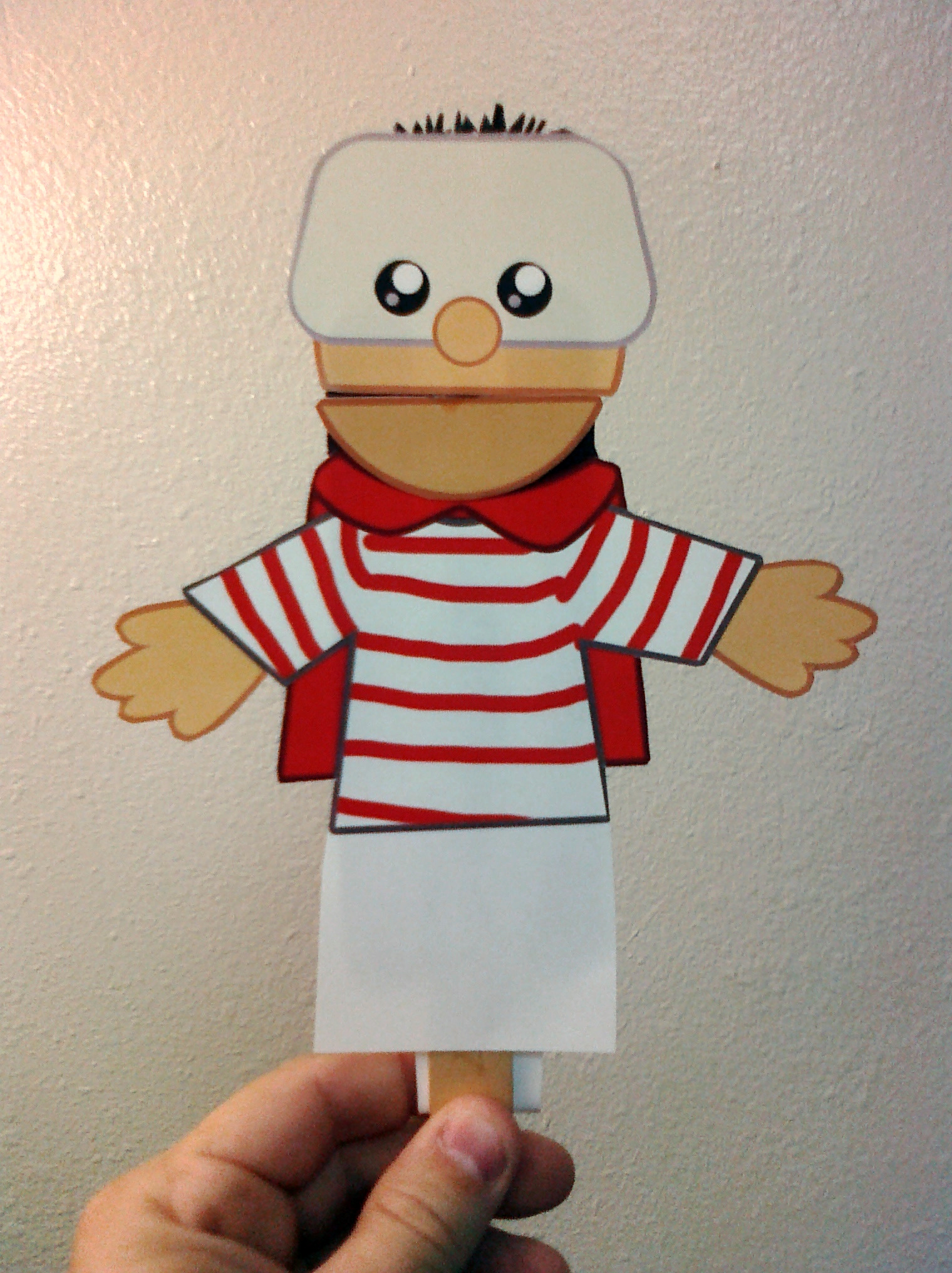

The script for this Sunday’s puppet lesson called for a second puppet character that resembled the first. Since I created the costume for our regular character from scratch, this wasn’t going to be easy or cheap. I started thinking about craft supplies, foam balls for heads, dowel rods for the body, elastic to create tension for the jaw. I even went as far as to look up simple puppet making online. Then I had this idea… why not make myself out of paper?

The first step was to draw the character out in Photoshop. (You can download the finished image as a PDF if you’d like to use it yourself) Then I printed it out on card stock with a color printer. You could just as easily draw your character directly on the paper though. Then I cut it out and cut a slit at the bottom of the black space. I slid a narrow strip of paper up through the slit and attached it with Super Glue to the top edge of the characters bottom lip. Instantly I was able to manipulate the mouth… but I had to use both hands.

I added some tongue depressors to the back for support with Super Glue. I added a short length of rubber band to the back to pull the mouth back up when I pulled down. Then I wrapped the end of the mouth manipulation strip around a bit of Popsicle stick so I could pull it down with one hand using my thumb. And that was it!

Check out the video of the finished puppet so you can see what I’m talking about here.

I’m very pleased with the result. I’ll defiantly be making more of these… and I’m pretty sure Little Scripture Man will become a regular on Sundays.

What do you think? Will you try your hand at making a paper puppet? Shoot me you thoughts in the comments.